- Home | Industry Update | Developing Biodegradable E-textiles: Addressing The Environm...

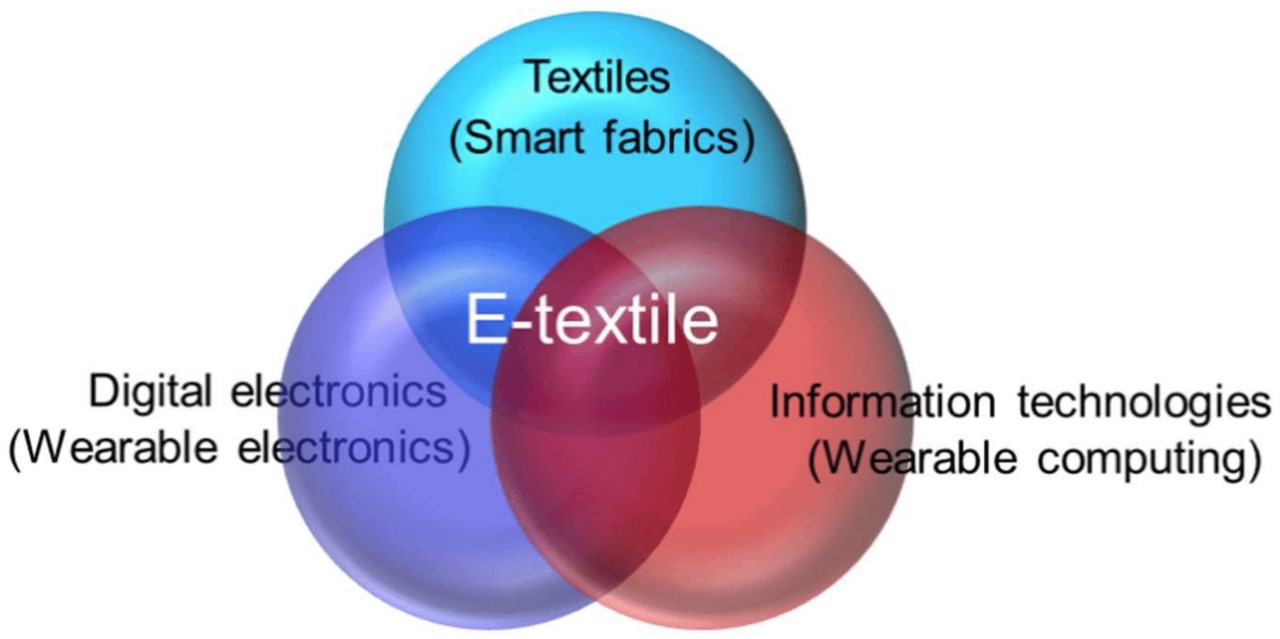

Developing Biodegradable E-textiles: Addressing The Environmental Impact Of Wearable Technology

A collaborative effort involving researchers from six leading UK universities (Southampton, West of England Bristol, Exeter, Cambridge, Leeds, and Bath) has achieved a significant breakthrough in sustainable technology. They have successfully developed a novel method for creating "Smart, Wearable, and Eco-friendly Electronic Textiles" (SWEET). These innovative fabrics integrate advanced electronic functionalities, such as sensors or embedded lights, while simultaneously ensuring their complete biodegradability at the end of their lifecycle.

To fabricate a biodegradable e-textile, the researchers employed a three-layered design. The foundation is a Tencel fabric, derived from wood pulp, providing a sustainable base. An interface layer is then introduced, followed by the sensor layer. For the electronic components, the team integrated graphene and a conductive polymer known as PEDOT: PSS. A key innovation lies in the manufacturing process. The researchers utilized inkjet printing to adhere these materials to the fabric. This technique minimizes water and energy consumption while virtually eliminating material waste, offering a significant environmental advantage.

To validate their creation, the researchers conducted a human trial. Five participants wore gloves incorporating the biodegradable e-textile. The fabric successfully measured electrocardiogram (ECG) signals and skin temperature, mirroring the capabilities of many commercially available smart wearables. This achievement marks a significant milestone: demonstrating reliable, industry-standard monitoring while adhering to strict environmental principles. As Shaila Afroj, a co-author of the study and associate professor of sustainable materials at the University of Exeter, emphasized in a statement, 'This research proves that sustainability and functionality can coexist, particularly in critical areas like healthcare.

Following successful trials in monitoring human physiological metrics, the team subjected SWEET to a rigorous biodegradability test. The fabric was interred in soil with a pH of 6.5 to 6.8 within a controlled environment: an incubator maintaining a temperature of approximately 29 degrees Celsius (84 degrees Fahrenheit) and a relative humidity of around 90%. After a four-month period, a significant degree of degradation was observed. The fabric exhibited a 48% weight reduction and a 98% loss in tensile strength. Notably, the graphene components demonstrated a remarkable 40-fold reduction in environmental impact compared to conventional wearable electrodes during decomposition. These findings were meticulously documented and published in the esteemed journal Energy and Environmental Materials.

01:05 PM, Jan 15

Other Related Topics

Industry Update

Kolkata Set to Become Textile Sourcing Hub as YARNEX and TEXINDIA Return in January 2026...view more

India Textile Industry 2025 Review: How US Tariffs Hit Exports, and the Road to Recovery...view more

Ludhiana MP Rajinder Gupta Presses Textile Sector Concerns in Meeting with FM Sitharaman...view more

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.jpg)

.png)

.jpg)

.jpg)